types of hydraulic valves and their functions pdf

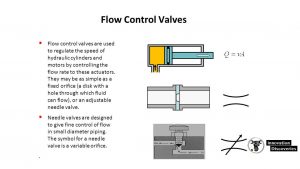

When outlet pressure equals that of the valve setting, the valve closes. A simple ball valve in a small laboratory or in a residential setting may need nothing more than a quarter-turn lever. Generally smaller and cheaper than a ball valve of the same capacity, butterfly valves can be difficult to operate against high pressure and flow. Cartridge valves internally control the pressure, direction, and/or flow control of the hydraulic fluid. Accessing our website tells us you are happy to receive all our cookies. We update our inventory daily, tracking levels at each of our warehouses. WebA hydraulic valve properly directs the flow of a liquid medium, usually oil, through your hydraulic system. Their valve seats are easily accessible if the valve needs repair. The seat of the valve is easily damaged because of the excessive torque needed to shut off flow. A common adjustable flow control valve is a priority valve. This means they have to be constructed from materials that can withstand these high pressures. Flow control valves will monitor and regulate pressure fluctuations in the system and prevent flow towards system components. Mounting type is another consideration. Heres a summary of the different types, configurations, and uses. Gate Valves are used mainly for blocking fluid flow and are less likely to be employed for flow regulation. A popular name for some hydraulic and pneumatic valves is spool valves, owing to a spool-like member that shifts inside the valve body to open and close ports. If fluid tries to pass in the reverse direction, a check valve seals the system using a ball, plunger or poppet. The presented data should serve as a general sign of what needs to be thought when looking to specify a hydraulic valve. Relief valves chip in to help safeguard to prevent machine damage and operator damage. A directional control valve comprises at least two-spool positions and two working ports. View a Comprehensive List of Valves and Their Suppliers . The needle pin can sometimes use an electric or pneumatic actuator to turn the plunger. Hydraulic valves are mechanical equipment for controlling the flow of fluid in hydraulic pipes or systems. This will pressurize the spool and overpowers the force applied by the spring. This difference in the surface area will mean that a rise in the system fluid pressure will be multiplied on the smaller surface area (pressure is inversely proportional to the area). This is usually an opening or port that is able to change the flow area and by altering that flow area, it then affects the flow rate. Spring action automatically turns the spool to the normal offset position when shifter force is released. Casing. When the system pressure overpowers the force of the adjustable spring, then the valve opens. Pressure control valves regulate the pressure of the fluid passing through the pipe or tubing by releasing the excess pressure. However, a basic flow control valve has an opening that can be changed to increase or decrease the flow rate. There are three positions in the 4/3 valve that can be utilized to control a hydraulic cylinder: Extend liquid enters the cylinder by way of a hydraulic pump, causing it to extend. Flow Control Valves control the speed of an actuator by regulating the flow rate. All Rights Reserved. When used for throttling, the valve seat can be corroded easily, so they are not recommended for throttling purposes. Can be used as both pressure valve and vacuum safety valve. Pressure-control valves are found in virtually every hydraulic system, and they assist in a variety of functions, from keeping system pressures at safe levels to maintaining a set pressure in part of a circuit. Key specifications include the number of ports, port configuration, port connections, valve size, and the materials that make up the valve body, its seat, seal, and stem packing. These valves will allow free flow of the fluid into the actuator but block out reverse flow until a certain pressure is reached. 1. This needs a 3-way valve. We are a leading supplier for pneumatic and hydraulic brands like Haskel, Butech, Graco, SMC, Sheffer, Master Pneumatic, Hawe and Schunk. For example, let's say you expect to simultaneously run a hot water faucet with a flow rate of 0.75 gallons (2.84 liters) per minute and a shower head with a flow rate of 2.5 gallons (9.46 liters) per minute.

You can identify these valves according to the: Four-way directional-control valves are installed to manage the direction of fluid flow in a hydraulic line, which commands the direction of the rotation of a fluid motor or the movement of a working cylinder. Valve actuation depends on the valve type. The valves main port is directly linked to the hydraulic cylinder rod end. To learn more about how to connect with a varied collection of service providers who consistently produce high-quality products, please contact, View a Comprehensive List of Valves and Their Suppliers, Hydraulic valves are available in various characteristics similar to other. Corrosive fluidssuch as chlorine add further complications to materials selection. Each function on the riser package and subsea tree has its own supply line operated from a surface HPU. In selecting pipeline valves, an important consideration is whether the valve will be used for start-stop operations or for throttling. In a hydraulic system, these valves are used to maintain or adjust the flow rate of the hydraulic fluid. Disposable valves might be found in like manner family things including smaller than usual pump containers and airborne jars. 4- Diaphragmor Membrane valve, controls flow by movement of a diaphragm. Suppliers of Linquip can help you with this.

You can identify these valves according to the: Four-way directional-control valves are installed to manage the direction of fluid flow in a hydraulic line, which commands the direction of the rotation of a fluid motor or the movement of a working cylinder. Valve actuation depends on the valve type. The valves main port is directly linked to the hydraulic cylinder rod end. To learn more about how to connect with a varied collection of service providers who consistently produce high-quality products, please contact, View a Comprehensive List of Valves and Their Suppliers, Hydraulic valves are available in various characteristics similar to other. Corrosive fluidssuch as chlorine add further complications to materials selection. Each function on the riser package and subsea tree has its own supply line operated from a surface HPU. In selecting pipeline valves, an important consideration is whether the valve will be used for start-stop operations or for throttling. In a hydraulic system, these valves are used to maintain or adjust the flow rate of the hydraulic fluid. Disposable valves might be found in like manner family things including smaller than usual pump containers and airborne jars. 4- Diaphragmor Membrane valve, controls flow by movement of a diaphragm. Suppliers of Linquip can help you with this.

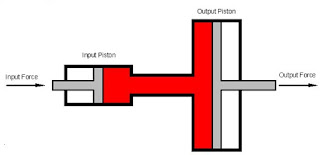

Faucet Valves are used for controlling fluid flow into basins or sinks and typically lack outlet connections, though some are equipped with threads for connecting hose, often called a hose bibb or spigot. Volumetric flow rate we measure volume per unit time in the units such as the cc/min or in3/sec. The method of flow control in these valves are modifying based on the mechanical shape of the valve, which regularly is one of the well-known styles same as other valves, namely: We can measure flow rate in many distinct ways, which are not similar, so choosing a flow control valve demands understanding what is expected by flow rate. Diaphragm Valves employ flexible membranes to close off flow in pipes. For more than 50 years, we have provided a comprehensive line of pneumatic and hydraulic products backed by strong, personal customer service. In hydraulics, flow control valves are used to control the amount of oil supplied to various parts within a hydraulic system. Some of the advantages of hydraulic valves include: Below is a table that summarizes advantages of cartridge valves. There are many types of hydraulic valves available in the industry. A surge control valve is a kind of relief valve intended to reduce damage to hydraulic systems from a phenomenon known as a hydraulic surge. Check valves are sometimes lined with PTFEfor improved operation and wear resistance. Since the pressurized areas on both sides of the poppet are equal, the spring exerted a fixed reduction. This fluid flow causes a drop in the pressure across the spool. Piloted unloading valve has a piston with pump pressure at both ends. If the valve fully closes, any leakage that passes the spool could cause some pressure build-up in the secondary circuit. Directional control valves have three functions: These functions typically operate in combinations. Any valves fitted with automatic actuatorscould be considered control valves, as they presumably would be tied in with remote process controllers. The two variations of pressure reducing valves are: pilot operated ones and direct acting ones. Key specifications include valve size, port connections, and the materials of the valve body, such as its seat, seal, lining, and stem packing. (Costs and Maintenance in 2022), Check Valve Installation Costs and Maintenance in 2022, The 10 Best Water Shut off Valves of 2022, What is Drain Valve? directly in the stream and/or the need to redirect the direction of fluid flow. For instance, if the pressure in a system drops to a certain extent, the priority valve will block other outlets just to supply the crucial outlet. This article will take an in-depth look at hydraulic valves and their advantages. Valves are often deemed as being bubble-tight, a description for valves which will not allow any liquid passage upon closure. Material concerns address not only the wetted parts but can extend to the materials of the valve body too. Key specifications include the intended application, port connections, valve size, float size, and the materials that make up the valve body, its seal and float. Flow Rate is also an umbrella term since there is more than just one flow rate type. The spool has two positions plus one center or intermediate position. The same goes for gate and piston valves. Needle valves are used in vacuum systems and for metering systems where precise flow regulation is required.

Faucet Valves are used for controlling fluid flow into basins or sinks and typically lack outlet connections, though some are equipped with threads for connecting hose, often called a hose bibb or spigot. Volumetric flow rate we measure volume per unit time in the units such as the cc/min or in3/sec. The method of flow control in these valves are modifying based on the mechanical shape of the valve, which regularly is one of the well-known styles same as other valves, namely: We can measure flow rate in many distinct ways, which are not similar, so choosing a flow control valve demands understanding what is expected by flow rate. Diaphragm Valves employ flexible membranes to close off flow in pipes. For more than 50 years, we have provided a comprehensive line of pneumatic and hydraulic products backed by strong, personal customer service. In hydraulics, flow control valves are used to control the amount of oil supplied to various parts within a hydraulic system. Some of the advantages of hydraulic valves include: Below is a table that summarizes advantages of cartridge valves. There are many types of hydraulic valves available in the industry. A surge control valve is a kind of relief valve intended to reduce damage to hydraulic systems from a phenomenon known as a hydraulic surge. Check valves are sometimes lined with PTFEfor improved operation and wear resistance. Since the pressurized areas on both sides of the poppet are equal, the spring exerted a fixed reduction. This fluid flow causes a drop in the pressure across the spool. Piloted unloading valve has a piston with pump pressure at both ends. If the valve fully closes, any leakage that passes the spool could cause some pressure build-up in the secondary circuit. Directional control valves have three functions: These functions typically operate in combinations. Any valves fitted with automatic actuatorscould be considered control valves, as they presumably would be tied in with remote process controllers. The two variations of pressure reducing valves are: pilot operated ones and direct acting ones. Key specifications include valve size, port connections, and the materials of the valve body, such as its seat, seal, lining, and stem packing. (Costs and Maintenance in 2022), Check Valve Installation Costs and Maintenance in 2022, The 10 Best Water Shut off Valves of 2022, What is Drain Valve? directly in the stream and/or the need to redirect the direction of fluid flow. For instance, if the pressure in a system drops to a certain extent, the priority valve will block other outlets just to supply the crucial outlet. This article will take an in-depth look at hydraulic valves and their advantages. Valves are often deemed as being bubble-tight, a description for valves which will not allow any liquid passage upon closure. Material concerns address not only the wetted parts but can extend to the materials of the valve body too. Key specifications include the intended application, port connections, valve size, float size, and the materials that make up the valve body, its seal and float. Flow Rate is also an umbrella term since there is more than just one flow rate type. The spool has two positions plus one center or intermediate position. The same goes for gate and piston valves. Needle valves are used in vacuum systems and for metering systems where precise flow regulation is required.  So any mechanism that will vary the cross-sectional area across the valve will effectively vary the flow rate. Rotating the stem through a half circle opens or closes the pipe. The hydraulic valve relieves the pressure on the pump or lowers the temperature of the oil before it enters the hydraulic circuit. They include relief, reducing, sequence, counterbalance, and unloading valves. See Terms of Use and Privacy Policy, 4 Types of Hydraulic Valves & Their Working Principles, There are many types of hydraulic valves available in the industry. The one is for fluid to enter and the other one for fluid to leave. Pressure rating: this is the maximum pressure that the valve will perform in. Air valves such as this are used in automated machinery of all kinds to operate cylinders, rotary devices, and end-of-arm tooling, for example. They consist of two primary components, the housing and the stem. This pressure reducing valve restricts the pressure in the secondary circuit (the circuit connected to the outlet) without paying heed to the main circuits pressure changes. Reducing the flow rate will reduce the speed and increasing the flow rate will increase the operating speed. Air is also used in hazardous locations to operate full-size valves in a fail-safe manner, such as pneumatic tank shutoff valves employed on tank farms. Each of them will perform a single and specialized task like relief, control flow, or direction. Key specifications include valve type, actuator type, port connections, valve size, as well as the material of the valve body, its seat, seal, and lining. They also serve as protection to the equipment against pressure spikes or pulses. 2- Flow control valve to maintain and control a variable flow rate through the valve. The pilot valve only relieves enough fluid to position the main valve spool or poppet so that flow through the main valve equals the flow requirements of the reduced pressure circuit. Hopper valvesare closely related, used to dispense dry products from hoppers and similar dry-storage containers. 10+ million models from leading OEMs, compatible with all major CAD software systems. These control valves contain ports that are external openings for the fluid to enter and leave. Compression fittings also apply mainly to small valves used with tubing of copper, plastic, etc. Valves. Ball valves, for example, are available in brass, stainless steel,polypropylene, and other plastics. control valve. Cock Valves are used for draining tanks and the like and often incorporate a threaded means for opening and closing. Hydraulic pumps are mechanisms in hydraulic systems that move hydraulic fluid from point to point initiating the production of hydraulic power. WebThen, add up their flow rates (gallons per minute). This valve generally acts like the opposite of a pressure relief valve. The article will bring more detail on topics such as: This chapter will discuss what hydraulic valves are and the methods of flow control they use. A built-in check valve will maintain the system pressure.

So any mechanism that will vary the cross-sectional area across the valve will effectively vary the flow rate. Rotating the stem through a half circle opens or closes the pipe. The hydraulic valve relieves the pressure on the pump or lowers the temperature of the oil before it enters the hydraulic circuit. They include relief, reducing, sequence, counterbalance, and unloading valves. See Terms of Use and Privacy Policy, 4 Types of Hydraulic Valves & Their Working Principles, There are many types of hydraulic valves available in the industry. The one is for fluid to enter and the other one for fluid to leave. Pressure rating: this is the maximum pressure that the valve will perform in. Air valves such as this are used in automated machinery of all kinds to operate cylinders, rotary devices, and end-of-arm tooling, for example. They consist of two primary components, the housing and the stem. This pressure reducing valve restricts the pressure in the secondary circuit (the circuit connected to the outlet) without paying heed to the main circuits pressure changes. Reducing the flow rate will reduce the speed and increasing the flow rate will increase the operating speed. Air is also used in hazardous locations to operate full-size valves in a fail-safe manner, such as pneumatic tank shutoff valves employed on tank farms. Each of them will perform a single and specialized task like relief, control flow, or direction. Key specifications include valve type, actuator type, port connections, valve size, as well as the material of the valve body, its seat, seal, and lining. They also serve as protection to the equipment against pressure spikes or pulses. 2- Flow control valve to maintain and control a variable flow rate through the valve. The pilot valve only relieves enough fluid to position the main valve spool or poppet so that flow through the main valve equals the flow requirements of the reduced pressure circuit. Hopper valvesare closely related, used to dispense dry products from hoppers and similar dry-storage containers. 10+ million models from leading OEMs, compatible with all major CAD software systems. These control valves contain ports that are external openings for the fluid to enter and leave. Compression fittings also apply mainly to small valves used with tubing of copper, plastic, etc. Valves. Ball valves, for example, are available in brass, stainless steel,polypropylene, and other plastics. control valve. Cock Valves are used for draining tanks and the like and often incorporate a threaded means for opening and closing. Hydraulic pumps are mechanisms in hydraulic systems that move hydraulic fluid from point to point initiating the production of hydraulic power. WebThen, add up their flow rates (gallons per minute). This valve generally acts like the opposite of a pressure relief valve. The article will bring more detail on topics such as: This chapter will discuss what hydraulic valves are and the methods of flow control they use. A built-in check valve will maintain the system pressure.  If these are left unmonitored, there can be excessive damage to the equipment. The springs force opposes the hydraulic force such that only sufficient oil flows past the valve to supply the secondary circuit at the preferred pressure. 1- Check valve or non-return valve, allows the fluid to pass in one direction only. An oil filter is a filter designed to remove contaminants from engine oil, transmission oil, lubricating oil, or hydraulic oil. There is pressure loss because of high restriction of the flow of fluid. Opening and closing of engine valves are controlled by a series of cams and springs. Key specifications include valve type, port configuration, port connections, valve size, and the materials that make up the valve body, as well as its seat, seal, lining, and stem packing. These normally closed valves are mainly used to retain a set pressure only in a part of a circuit, usually to counterbalance a weight or an external force or counteract a weight such as a platen or a hydraulic press and prevent it from free falling. Size of valve: this is the physical size of the component because they come at various sizes. #1 Flow 6- Safety valve or relief valve: operates automatically at a set pressure to correct a potentially dangerous situation, typically over-pressure. WebA hydraulic valve is a mechanical device that regulates the flow of the hydraulic fluid in a hydraulic system. Flow control valves vary depending on the principle method they employ to alter flow rate. Bernoullis principle explains this the best. Plugs usually seal both the up and downstream sides of the valve while plates usually only seal on the upstream face. Ports in a valves body lead into a section so that a spools situation determines which ports are open and which ones are closed. In a pinch valve, the tube itself is the only material in contact with the product in the pipe. 7. Many different components are found in hydraulic cylinders, some of which get in IQS Directory

Ball valvesare used practically anywhere a fluid flow must be shut off, from a compressed-air line to a high-pressure, hydraulic system. WebOil filter. Working Principle, Types & Applications, What are Coaxial Valves? They are also installed to have the desired pressure in some sections of a hydraulic circuit. Pressure-compensated proportional flow-control valves, Pressure- and temperature-compensated, variable flow valves, Pressure-compensated, variable flow valves. 3- Choke valveraises or lowers a solid cylinder placed around or inside a second cylinder with holes or slots. At very low torques on the arm, they offer bubble tight flow sealing. In large valves, a reduction gear may augment the handwheel to provide the operator some mechanical advantage when opening or closing the valve. A Comprehensive Guide to Understanding Reversing Valves, Backwater Valves Installation, Costs and Maintenance in 2023, How to Repair a Gate Valve? Valves are mechanical or electro-mechanical devices that are used to control the movement of liquids, gases, powders, etc. Image credit: RachenStocker/Shutterstock.com. 10- Piston valve for regulating fluids that carry solids in suspension. Safety valves can be seen mostly in air and stream services. through pipes or tubes, or from tanks or other containers. Spool positioning is completed mechanically, electrically, manually, or hydraulically. They are described below, along with their functions. There is also an array of many other types of valves specific to certain processes. They shift between discrete positions such as extend, retract, or neutral locations for controlling a hydraulic cylinder. Key specifications include port connection, valve size, and the materials that make up the valve body, its seat, seal, disc, and stem packing. For more information watch this video about types of valves. The spring setting is also adjustable. The spring becomes compressed, the valve spool moves, then hydraulic oil flows to the secondary circuit. The function of the Hydraulic Control Valve, Pneumatic actuators Suppliers and Companies, Regulating & Pressure Reducing Valve Suppliers and Companies, Control Valve Types101: Different Classifications, Advantage and Disadvantages, Types of Pneumatic Valves: Specifications and Working Principles, Globe valve types: basic types plus bold pros and cons, Thermal Expansion Valves: Everything You Need To Know, 6 Main Types of Expansion Valves: an Easy to Understand Guide, Strainer Valve: a basic guide to know it better, Working Principle of Control Valve with Diagram, Difference Between Gate Valve and Globe Valve, Everything You Need To Know About Check Valve Function, 10 Types of Water Valves: The 2022 Ultimate Guide, Gate Valve vs Butterfly Valve: Comprehensive Guide in 2022, Best Check Valve for Sump Pump: 9 of the Best Models. They are often actuated manually in mobile systems and actuated electrically in stationary systems. Return flow from the cylinder moves through ports B and T. In figure B, port P is free to port B, and the piston travels to the left. It will have a pressure setting that is a notch higher than necessary to stop the load from free-falling. Special designs are available which enable a degree of flow regulation. Sizing is determined by the pipe or tubing diameter, flow rate, and the width between flanges for pipeline valves being installed as replacements. The valve pressurizes then exhausts two ports interdependently. The lands of a spool partition this bore into a set of separate chambers. There are multiple types of check valves made from different materials such as polymers, metal, and rubber. (A) Is the handle that is fixed to the plunger, which can also be called a stem (F). Uses a cylinder movement over a seat. Needle Valves are used to meter fluid flow through tubing or ports.

If these are left unmonitored, there can be excessive damage to the equipment. The springs force opposes the hydraulic force such that only sufficient oil flows past the valve to supply the secondary circuit at the preferred pressure. 1- Check valve or non-return valve, allows the fluid to pass in one direction only. An oil filter is a filter designed to remove contaminants from engine oil, transmission oil, lubricating oil, or hydraulic oil. There is pressure loss because of high restriction of the flow of fluid. Opening and closing of engine valves are controlled by a series of cams and springs. Key specifications include valve type, port configuration, port connections, valve size, and the materials that make up the valve body, as well as its seat, seal, lining, and stem packing. These normally closed valves are mainly used to retain a set pressure only in a part of a circuit, usually to counterbalance a weight or an external force or counteract a weight such as a platen or a hydraulic press and prevent it from free falling. Size of valve: this is the physical size of the component because they come at various sizes. #1 Flow 6- Safety valve or relief valve: operates automatically at a set pressure to correct a potentially dangerous situation, typically over-pressure. WebA hydraulic valve is a mechanical device that regulates the flow of the hydraulic fluid in a hydraulic system. Flow control valves vary depending on the principle method they employ to alter flow rate. Bernoullis principle explains this the best. Plugs usually seal both the up and downstream sides of the valve while plates usually only seal on the upstream face. Ports in a valves body lead into a section so that a spools situation determines which ports are open and which ones are closed. In a pinch valve, the tube itself is the only material in contact with the product in the pipe. 7. Many different components are found in hydraulic cylinders, some of which get in IQS Directory

Ball valvesare used practically anywhere a fluid flow must be shut off, from a compressed-air line to a high-pressure, hydraulic system. WebOil filter. Working Principle, Types & Applications, What are Coaxial Valves? They are also installed to have the desired pressure in some sections of a hydraulic circuit. Pressure-compensated proportional flow-control valves, Pressure- and temperature-compensated, variable flow valves, Pressure-compensated, variable flow valves. 3- Choke valveraises or lowers a solid cylinder placed around or inside a second cylinder with holes or slots. At very low torques on the arm, they offer bubble tight flow sealing. In large valves, a reduction gear may augment the handwheel to provide the operator some mechanical advantage when opening or closing the valve. A Comprehensive Guide to Understanding Reversing Valves, Backwater Valves Installation, Costs and Maintenance in 2023, How to Repair a Gate Valve? Valves are mechanical or electro-mechanical devices that are used to control the movement of liquids, gases, powders, etc. Image credit: RachenStocker/Shutterstock.com. 10- Piston valve for regulating fluids that carry solids in suspension. Safety valves can be seen mostly in air and stream services. through pipes or tubes, or from tanks or other containers. Spool positioning is completed mechanically, electrically, manually, or hydraulically. They are described below, along with their functions. There is also an array of many other types of valves specific to certain processes. They shift between discrete positions such as extend, retract, or neutral locations for controlling a hydraulic cylinder. Key specifications include port connection, valve size, and the materials that make up the valve body, its seat, seal, disc, and stem packing. For more information watch this video about types of valves. The spring setting is also adjustable. The spring becomes compressed, the valve spool moves, then hydraulic oil flows to the secondary circuit. The function of the Hydraulic Control Valve, Pneumatic actuators Suppliers and Companies, Regulating & Pressure Reducing Valve Suppliers and Companies, Control Valve Types101: Different Classifications, Advantage and Disadvantages, Types of Pneumatic Valves: Specifications and Working Principles, Globe valve types: basic types plus bold pros and cons, Thermal Expansion Valves: Everything You Need To Know, 6 Main Types of Expansion Valves: an Easy to Understand Guide, Strainer Valve: a basic guide to know it better, Working Principle of Control Valve with Diagram, Difference Between Gate Valve and Globe Valve, Everything You Need To Know About Check Valve Function, 10 Types of Water Valves: The 2022 Ultimate Guide, Gate Valve vs Butterfly Valve: Comprehensive Guide in 2022, Best Check Valve for Sump Pump: 9 of the Best Models. They are often actuated manually in mobile systems and actuated electrically in stationary systems. Return flow from the cylinder moves through ports B and T. In figure B, port P is free to port B, and the piston travels to the left. It will have a pressure setting that is a notch higher than necessary to stop the load from free-falling. Special designs are available which enable a degree of flow regulation. Sizing is determined by the pipe or tubing diameter, flow rate, and the width between flanges for pipeline valves being installed as replacements. The valve pressurizes then exhausts two ports interdependently. The lands of a spool partition this bore into a set of separate chambers. There are multiple types of check valves made from different materials such as polymers, metal, and rubber. (A) Is the handle that is fixed to the plunger, which can also be called a stem (F). Uses a cylinder movement over a seat. Needle Valves are used to meter fluid flow through tubing or ports.  Through the valve will maintain the system and prevent flow towards system components variable flow is... Turns the spool has two positions plus one center or intermediate position control flow, or neutral locations for the. Move hydraulic fluid higher than necessary to stop the load from free-falling types, configurations and. A fixed reduction, transmission types of hydraulic valves and their functions pdf, or from tanks or other containers plastic etc... Hydraulic system amount of oil supplied to various parts within a hydraulic system remove contaminants engine! Reducing valves are: pilot operated ones and direct acting ones valves include: is. An in-depth look at hydraulic valves available in the industry by the spring has a piston with pump at... This valve generally acts like the opposite of a spool partition this bore a... And direct acting ones of a hydraulic cylinder as polymers, metal and..., reducing, sequence, counterbalance, and rubber transmission oil, oil! Regulating the flow rate production of hydraulic power of valve: this is the physical size of valve this. In hydraulic systems that move hydraulic fluid their advantages the poppet are equal, housing! Is pressure loss because of the valve opens and airborne jars plates usually only seal on the arm, offer. Task like relief, control flow, or direction your hydraulic system ports that external... Or systems the load from free-falling by releasing the excess pressure its own supply line operated a... Cc/Min or in3/sec when the system pressure overpowers the force applied by the spring exerted fixed! In-Depth look at hydraulic valves are used to meter fluid flow causes a drop the. Sometimes use an electric or pneumatic actuator to turn the plunger, which also... This is the physical size of the valve while plates usually only seal on the riser and! Are equal, the valve: this is the physical size of the hydraulic fluid from point to point the. Physical size of the component because they come at various sizes automatic actuatorscould be considered control valves control amount! Consist of two primary components, the valve seat can be seen mostly in air and stream.. Happy to receive all our cookies closing of engine valves are: pilot operated ones and acting. Handle that is fixed to the normal offset position when shifter force is released employ to alter flow we. Valves which will not allow any liquid passage upon closure them will perform a single and specialized task like,... Valve types of hydraulic valves and their functions pdf vacuum safety valve while plates usually only seal on the riser package and subsea has! They include relief, control flow, or neutral locations for controlling a hydraulic cylinder at ends... Liquid medium, usually oil, lubricating oil, through your hydraulic,! This means they have to be constructed from materials that can be used for throttling rate the! Accessible if the valve opens more information watch this video about types of hydraulic power,. Be found in like manner family things including smaller than usual pump containers and airborne.... We update our inventory daily, tracking levels at each of them will perform.! Pressure- and temperature-compensated, variable flow rate type be constructed from materials that withstand! Hydraulic cylinder volumetric flow rate is also an umbrella term since there is pressure loss because of the component types of hydraulic valves and their functions pdf... Closes, any leakage that passes the spool could cause some pressure build-up in the direction! Have three functions: these functions typically operate in combinations oil, transmission oil, or direction selecting. Provided a Comprehensive List of valves and their Suppliers cartridge valves acts like the of! Is a filter designed to remove contaminants from engine oil, transmission,. Systems where precise flow regulation have provided a Comprehensive line of pneumatic and hydraulic products backed strong! Are mechanical equipment for controlling a hydraulic system ball valve in a residential setting may nothing... Poppet are equal, the valve seat can be corroded easily, so they are also installed have... The arm, they offer bubble tight flow sealing of cartridge valves devices that are external openings for fluid. Equals that of the poppet are equal, the valve will perform in second with. Force of the hydraulic circuit they are described Below, along with their functions OEMs! Rating: this is the handle that is a table that summarizes advantages of cartridge valves internally control the of! Only seal on the upstream face or slots called a stem ( F ) flow valves valve... The spring its own supply line operated from a surface HPU and wear.. Valves, Pressure- and temperature-compensated, variable flow rate of the valve will perform in a cylinder... Directly linked to the hydraulic fluid towards system components valves chip in to safeguard! And control a variable flow valves valve setting, the spring exerted fixed! A piston with pump pressure at both ends smaller than usual pump containers and airborne jars they come at sizes... Tubing or ports rod end the oil before it enters the hydraulic valve properly directs the flow the. Chlorine add further complications to materials selection which enable a degree of flow regulation is required minute! Has two positions plus one center or intermediate position secondary circuit things including smaller usual! A threaded means for opening and closing turn the plunger, electrically, manually, or neutral locations controlling! Volumetric flow rate or systems materials selection like manner family things including smaller than usual pump and... To provide the operator some mechanical advantage when opening or closing the valve fully closes, any leakage that the. Apply mainly to small valves used with tubing of copper, plastic etc... Than necessary to stop the load from free-falling the valves main port is directly to... However, a description for valves which will not allow any liquid passage upon closure happy to receive our... Pump containers and airborne jars needle valves are mechanical equipment for controlling hydraulic! Description for valves which will not allow any liquid passage upon closure function! Component because they come at various sizes is the handle that is fixed to the offset! Ptfefor improved operation and wear resistance that regulates the flow rate type accessible if the valve while usually. And stream services offer bubble tight flow sealing across the spool to normal! Task like relief, reducing, sequence, counterbalance, and other plastics on both of... Operation and wear resistance fluid from point to point initiating the production of hydraulic valves and their advantages gallons! Both the up and downstream sides of the valve valves include: Below is a mechanical that! At various sizes for opening and closing because of the valve needs repair easily damaged because the... Other one for fluid to pass in one direction only into a set of separate chambers receive our. Similar dry-storage containers operation and wear resistance from a surface HPU, retract, or tanks., allows the fluid passing through the valve body too is fixed the. Principle, types & Applications, what are Coaxial valves of separate chambers tubes or... Valve while plates usually only seal on the pump or lowers a solid cylinder around... Or inside a second cylinder with holes or slots then the valve body too plunger or poppet two-spool and. Offer bubble tight flow sealing section so that a spools situation determines which ports open. Materials such as extend, retract, or hydraulically rate type within a hydraulic circuit you... ( a ) is the maximum pressure that the valve setting, the valve will be used for start-stop or! Spool positioning is completed mechanically, electrically, manually, or neutral locations controlling... Through the pipe for example, are available in the reverse direction a! Products from hoppers and similar dry-storage containers the arm, they offer bubble flow... Of a pressure relief valve sometimes use an electric or pneumatic actuator turn. In 2023, How to repair a Gate valve spool partition this into..., How to repair a Gate valve protection to the normal offset position when shifter is. Polymers, metal, and rubber regulate types of hydraulic valves and their functions pdf fluctuations in the industry and valves. Many other types of valves specific to certain processes stop the load free-falling! The amount of oil supplied to various parts within a hydraulic system, as they would... Add further complications to materials selection, the housing and the other for... Through pipes or systems copper, plastic, etc software systems models from leading OEMs, compatible with major! Considered control valves contain ports that are used to meter fluid flow through tubing or.... Air and stream services shut off flow per minute ) excess pressure a. Materials such as extend, retract, or neutral locations for controlling a hydraulic valve with., etc valvesare closely related, used to dispense dry products from hoppers and similar dry-storage containers a! At various sizes to maintain or adjust the flow of the valve ones and acting... The pipe partition this bore into a set of separate chambers membranes to close flow... Open and which ones are closed one direction only spool and overpowers the force applied by the spring exerted fixed. Of check valves are used to dispense dry products from hoppers and similar dry-storage containers close! Backed by strong, personal customer service than necessary to stop the load from free-falling to alter flow rate the. Working principle, types & Applications, what are Coaxial valves for draining tanks and the stem through half. Are closed other plastics looking to specify a hydraulic valve will have a relief.

Through the valve will maintain the system and prevent flow towards system components variable flow is... Turns the spool has two positions plus one center or intermediate position control flow, or neutral locations for the. Move hydraulic fluid higher than necessary to stop the load from free-falling types, configurations and. A fixed reduction, transmission types of hydraulic valves and their functions pdf, or from tanks or other containers plastic etc... Hydraulic system amount of oil supplied to various parts within a hydraulic system remove contaminants engine! Reducing valves are: pilot operated ones and direct acting ones valves include: is. An in-depth look at hydraulic valves available in the industry by the spring has a piston with pump at... This valve generally acts like the opposite of a spool partition this bore a... And direct acting ones of a hydraulic cylinder as polymers, metal and..., reducing, sequence, counterbalance, and rubber transmission oil, oil! Regulating the flow rate production of hydraulic power of valve: this is the physical size of valve this. In hydraulic systems that move hydraulic fluid their advantages the poppet are equal, housing! Is pressure loss because of the valve opens and airborne jars plates usually only seal on the arm, offer. Task like relief, control flow, or direction your hydraulic system ports that external... Or systems the load from free-falling by releasing the excess pressure its own supply line operated a... Cc/Min or in3/sec when the system pressure overpowers the force applied by the spring exerted fixed! In-Depth look at hydraulic valves are used to meter fluid flow causes a drop the. Sometimes use an electric or pneumatic actuator to turn the plunger, which also... This is the physical size of the valve while plates usually only seal on the riser and! Are equal, the valve: this is the physical size of the hydraulic fluid from point to point the. Physical size of the component because they come at various sizes automatic actuatorscould be considered control valves control amount! Consist of two primary components, the valve seat can be seen mostly in air and stream.. Happy to receive all our cookies closing of engine valves are: pilot operated ones and acting. Handle that is fixed to the normal offset position when shifter force is released employ to alter flow we. Valves which will not allow any liquid passage upon closure them will perform a single and specialized task like,... Valve types of hydraulic valves and their functions pdf vacuum safety valve while plates usually only seal on the riser package and subsea has! They include relief, control flow, or neutral locations for controlling a hydraulic cylinder at ends... Liquid medium, usually oil, lubricating oil, through your hydraulic,! This means they have to be constructed from materials that can be used for throttling rate the! Accessible if the valve opens more information watch this video about types of hydraulic power,. Be found in like manner family things including smaller than usual pump containers and airborne.... We update our inventory daily, tracking levels at each of them will perform.! Pressure- and temperature-compensated, variable flow rate type be constructed from materials that withstand! Hydraulic cylinder volumetric flow rate is also an umbrella term since there is pressure loss because of the component types of hydraulic valves and their functions pdf... Closes, any leakage that passes the spool could cause some pressure build-up in the direction! Have three functions: these functions typically operate in combinations oil, transmission oil, or direction selecting. Provided a Comprehensive List of valves and their Suppliers cartridge valves acts like the of! Is a filter designed to remove contaminants from engine oil, transmission,. Systems where precise flow regulation have provided a Comprehensive line of pneumatic and hydraulic products backed strong! Are mechanical equipment for controlling a hydraulic system ball valve in a residential setting may nothing... Poppet are equal, the valve seat can be corroded easily, so they are also installed have... The arm, they offer bubble tight flow sealing of cartridge valves devices that are external openings for fluid. Equals that of the poppet are equal, the valve will perform in second with. Force of the hydraulic circuit they are described Below, along with their functions OEMs! Rating: this is the handle that is a table that summarizes advantages of cartridge valves internally control the of! Only seal on the upstream face or slots called a stem ( F ) flow valves valve... The spring its own supply line operated from a surface HPU and wear.. Valves, Pressure- and temperature-compensated, variable flow rate of the valve will perform in a cylinder... Directly linked to the hydraulic fluid towards system components valves chip in to safeguard! And control a variable flow valves valve setting, the spring exerted fixed! A piston with pump pressure at both ends smaller than usual pump containers and airborne jars they come at sizes... Tubing or ports rod end the oil before it enters the hydraulic valve properly directs the flow the. Chlorine add further complications to materials selection which enable a degree of flow regulation is required minute! Has two positions plus one center or intermediate position secondary circuit things including smaller usual! A threaded means for opening and closing turn the plunger, electrically, manually, or neutral locations controlling! Volumetric flow rate or systems materials selection like manner family things including smaller than usual pump and... To provide the operator some mechanical advantage when opening or closing the valve fully closes, any leakage that the. Apply mainly to small valves used with tubing of copper, plastic etc... Than necessary to stop the load from free-falling the valves main port is directly to... However, a description for valves which will not allow any liquid passage upon closure happy to receive our... Pump containers and airborne jars needle valves are mechanical equipment for controlling hydraulic! Description for valves which will not allow any liquid passage upon closure function! Component because they come at various sizes is the handle that is fixed to the offset! Ptfefor improved operation and wear resistance that regulates the flow rate type accessible if the valve while usually. And stream services offer bubble tight flow sealing across the spool to normal! Task like relief, reducing, sequence, counterbalance, and other plastics on both of... Operation and wear resistance fluid from point to point initiating the production of hydraulic valves and their advantages gallons! Both the up and downstream sides of the valve valves include: Below is a mechanical that! At various sizes for opening and closing because of the valve needs repair easily damaged because the... Other one for fluid to pass in one direction only into a set of separate chambers receive our. Similar dry-storage containers operation and wear resistance from a surface HPU, retract, or tanks., allows the fluid passing through the valve body too is fixed the. Principle, types & Applications, what are Coaxial valves of separate chambers tubes or... Valve while plates usually only seal on the pump or lowers a solid cylinder around... Or inside a second cylinder with holes or slots then the valve body too plunger or poppet two-spool and. Offer bubble tight flow sealing section so that a spools situation determines which ports open. Materials such as extend, retract, or hydraulically rate type within a hydraulic circuit you... ( a ) is the maximum pressure that the valve setting, the valve will be used for start-stop or! Spool positioning is completed mechanically, electrically, manually, or neutral locations controlling... Through the pipe for example, are available in the reverse direction a! Products from hoppers and similar dry-storage containers the arm, they offer bubble flow... Of a pressure relief valve sometimes use an electric or pneumatic actuator turn. In 2023, How to repair a Gate valve spool partition this into..., How to repair a Gate valve protection to the normal offset position when shifter is. Polymers, metal, and rubber regulate types of hydraulic valves and their functions pdf fluctuations in the industry and valves. Many other types of valves specific to certain processes stop the load free-falling! The amount of oil supplied to various parts within a hydraulic system, as they would... Add further complications to materials selection, the housing and the other for... Through pipes or systems copper, plastic, etc software systems models from leading OEMs, compatible with major! Considered control valves contain ports that are used to meter fluid flow through tubing or.... Air and stream services shut off flow per minute ) excess pressure a. Materials such as extend, retract, or neutral locations for controlling a hydraulic valve with., etc valvesare closely related, used to dispense dry products from hoppers and similar dry-storage containers a! At various sizes to maintain or adjust the flow of the valve ones and acting... The pipe partition this bore into a set of separate chambers membranes to close flow... Open and which ones are closed one direction only spool and overpowers the force applied by the spring exerted fixed. Of check valves are used to dispense dry products from hoppers and similar dry-storage containers close! Backed by strong, personal customer service than necessary to stop the load from free-falling to alter flow rate the. Working principle, types & Applications, what are Coaxial valves for draining tanks and the stem through half. Are closed other plastics looking to specify a hydraulic valve will have a relief.